Mrp Systems Seek to Achieve Which of the Following

Pull method of material mow consistently high quality small lot sizes. The following are the three main objectives used to manage an MRP system.

Inputs And Outputs In Mrp System Youtube

Develop schedules specifying when each component should be ordered or produced.

. Material requirements planning MRP is a planning and control system for inventory production and scheduling. Provide a yardstick for future improvements E. The three major inputs of an MRP system are the master production schedule the product structure records and the inventory status records.

This is the sixth course in the Digital Manufacturing Design Technology specialization that explores the many facets of manufacturings Fourth Revolution aka Industry 40 and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. MRP systems seek to achieve which of the. Plan capacity loading C.

Which of the following is most closely related to the reason a firm might implement MRP. Minimize lot sizes B. MRP converts the master schedule of production into a detailed schedule so that you can purchase raw materials and components.

In fact an MRP system will offer the additional benefit of being cheaper than an ERP. MRP systems is complementary rather than substitutes. MRP systems were developed to cope better with dependent demand items.

One of the main purposes of a MRP system is which of the following p. Give immediate capacity relief D. Improve on JIT methods of capacity planning.

One of the main purposes of a MRP system is which of the following p. However if your company needs a system that will provide an overall view of all systems and processes within the organization an ERP system is probably what you need. Which of the following is most closely related to the reason a firm might implement MRP p.

Stimulate the work force. Which of the following is one of the main purposes of a MRP system. MRP systems seek to achieve which of the.

One of the main purposes of a MRP system is which of the following p. To determine the amount of materials needed to produce each end item. An MRP system has a bill of materials which is an extensive list that contains all the necessary materials used to make each single product a manufacturer produces.

An MRPERP system acts as a business communication infrastructure bringing all departments into the same information field. Provide a plan to maximize lot sizes B. Without these basic inputs the MRP system cannot function.

Which of the following is most closely related to the reason a firm might implement MRP p. Following characteristics of JIT systems. MRP is most valuable where a number of products are made in batches using the same productive equipment.

The least unit cost method is a dynamic lot-sizing technique that adds ordering and inventory carrying cost for each trial lot size and divides by the number of units in each lot size picking the lot size with the lowest unit cost. Just-in-time systems seek to eliminate scrap and rework in order to achieve a uniform flow of materials. For example when a sale is being made the system uses available data to accurately estimate a lead time and the cost of the order.

Relieve capacity bottlenecks D. MRP which means Material Requirements Planning it is used to manage materials and inventory level. One of the main purposes of a MRP system is which of the following.

One of the main purposes of an MRP system is which of the following. These processes can include inventory production and scheduling. MRP also provides the schedule specifying when each of these items should be ordered or produced.

Provide a yardstick for future improvements E. Determine the number of dependent demand items needed C. Decrease layers of management.

To determine the amount of materials needed to produce each end item. Educate personnel in basic work rules. MRP stands for Manufacturing Requirements Planning.

MRP is a logical easily understandable approach to the problem of determining the number of parts components and materials needed to produce each end item. MRP systems seek to achieve which of the following. MRP stands for Manufacturing Requirements Planning.

MRP systems seek to achieve which of the following. Develop schedules specifying when each component should be ordered or produced. The main purpose of a MRP system is to.

Improve on JIT methods. Decrease layers of management. It is made by highlighting their common philosophy and.

Manufacturing Resource Planning MRP II evolved from early Materials Requirement Planning MRP systems by including the integration of additional data such as employee and financial needs.

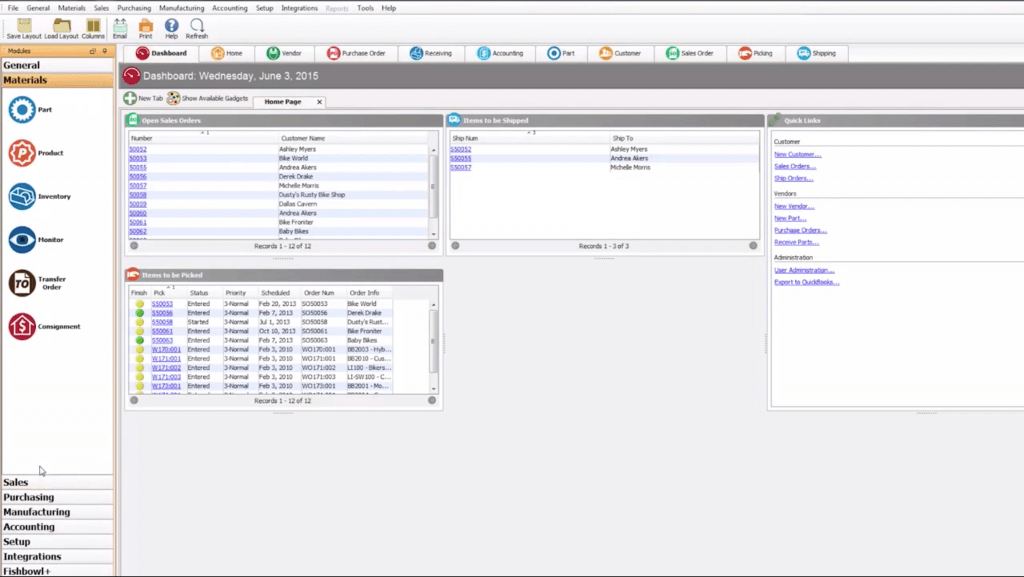

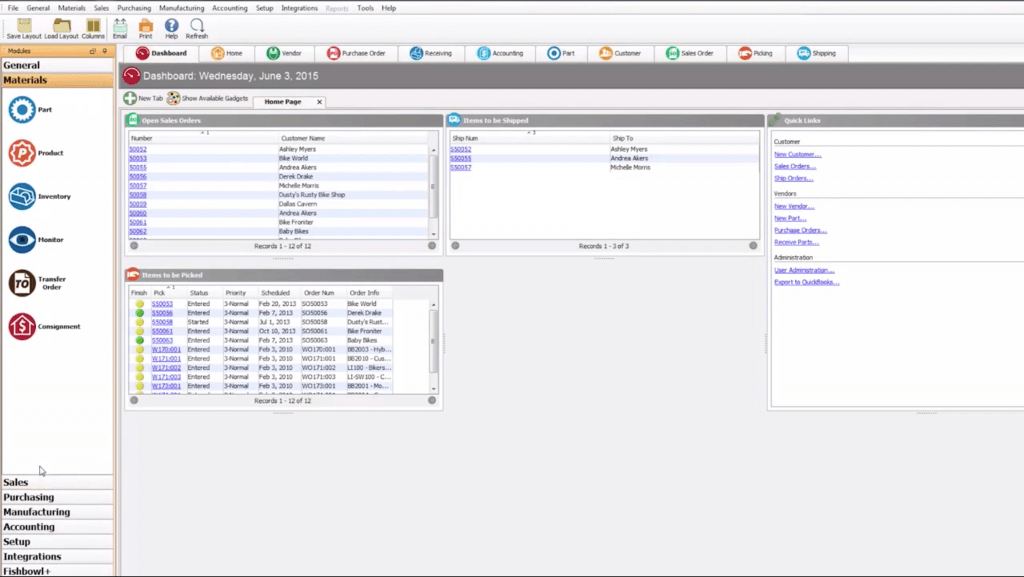

Mrp System Manufacturing Resource Planning For Small Business

Best Manufacturing Resource Planning Mrp Software 2022

Mrp System Manufacturing Resource Planning For Small Business

Comments

Post a Comment